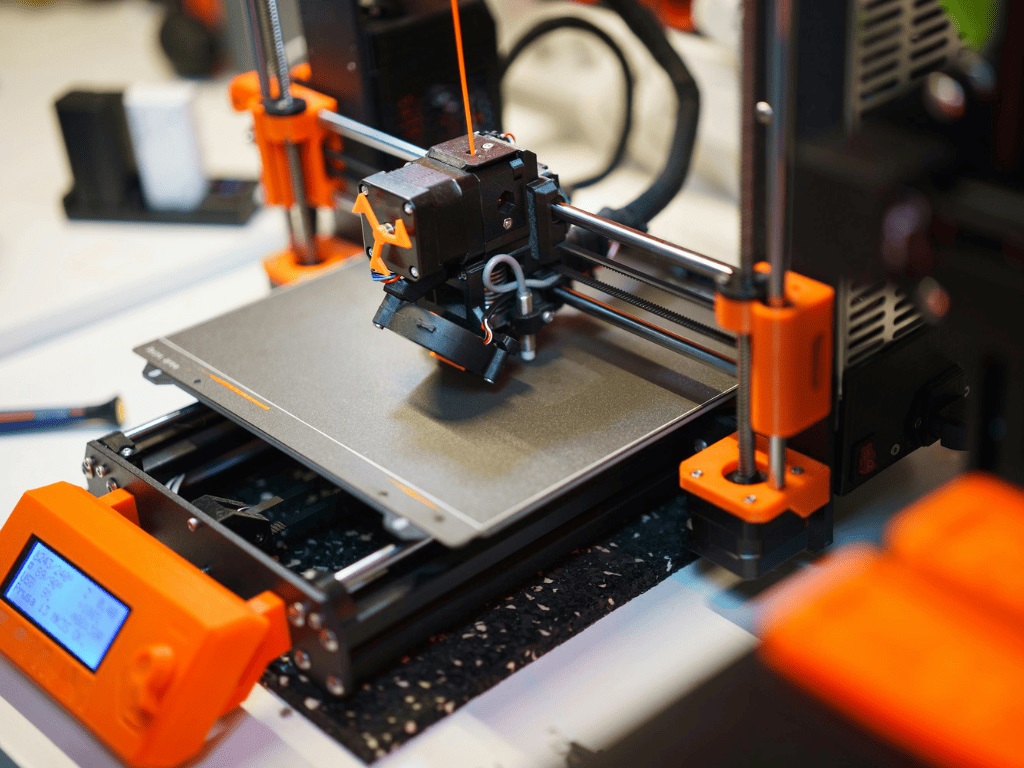

Printing at home a broken washing machine part or a LEGO piece may become a reality in the coming decades. Since their emergence in the late 1980s, 3D printers have evolved to become one of the most promising technologies for manufacturing goods. Although it is still a relatively young technology, its application in sectors such as construction —in Japan, a 3D printed train station was built in less than six hours—, automotive, aerospace, pharmaceuticals and food is already enabling significant efficiency gains and greater product customisation.

In the field of medicine, their potential is equally significant. Today, these printers are primarily used to create implants and custom-made prostheses, but in the coming years they are expected to advance towards the bioprinting of functional living tissues that can be integrated into the human body. If successfully developed, this could enable the treatment of complex injuries and degenerative diseases through the restoration of organs, bones, and other biological tissues.

However, the innovation of these printers is not just limited to improving production processes. It goes further. It can help decentralise manufacturing chains, bringing manufacturers and consumers closer together, and gradually become more common in households, as happened with televisions and computers in the past. So far, their presence has been concentrated in a few countries due to economies of scale and the need for skilled workers. This trend could change if the fragmentation of international supply chains accelerates. While trade in physical goods is subject to tariffs, logistical constraints and delivery times, digital design files can be shared instantly across the globe. When it comes to domestic use, the possibilities they offer are many: from repairing appliances and furniture to creating toys, printing food, or developing school projects. Compared to transporting goods, the environmental footprint of sharing a downloadable, ready-to-print file is also considerably lower.

For more information, see: Andrenelli, Andrea and Javier López-González. "3D printing and international trade. What is the evidence to date?" OECD Trade Policy Papers, n.º 256, París: OECD Publishing, 2021; Freund, Caroline, Alen Mulabdic, and Michele Ruta. "Is 3D printing a threat to global trade? The trade effects you didn't hear about." Journal of International Economics 138, 2022; Oficina Nacional de Prospectiva y Estrategia. Resilient EU2030. Madrid: Oficina Nacional de Prospectiva y Estrategia, 2023; Rifkin, Jeremy. "Gracias a la impresión 3D, la era de los aranceles tiene los días contados." El País; Cubo Mateo, Nieves. "3D-printed grafts: shaping the future of bone and tissue regeneration." The Conversation; and Notoya, Kiuko. "How Japan Built a 3D-Printed Train Station in 6 Hours." The New York Times.